Tissue Rewinding Machine Installation & Factory Relocation

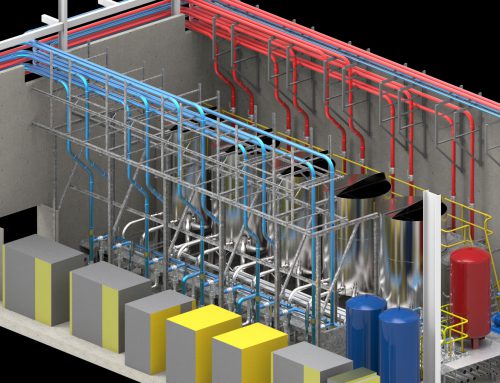

Our customer required relocation to larger premises to accommodate a brand new Italian tissue rewinding machine, along with the installation of wrapping & bundling lines and the relocation of an existing machine from their current factory. A second machine was to have good components removed and sent to a sister site with a similar machine in the South Island and the remainder of the machine was to be scrapped.

Concentric Engineered Solutions Ltd provided project management, relocation and installation services for the whole job and engaged Matched Ltd to supply additional mechanical labour and Machinery Relocations Ltd to provide transportation and logistics.

The new machine arrived in 15 x 40’ containers which were devanned in order and the machine components placed on base plates installed in the factory prior to the machine’s arrival. Levelling and alignment were undertaken with the OEM’s technicians. Once commissioning of the new machine was underway the machine to be relocated from the old factory was labelled, disassembled and transported to the new factory.

Some of the challenges encountered were:

- Late delivery of the new machine.

- A fire in the machine to be relocated to the new factory prior to decommissioning.

- Managing labour as work progressed in advance of the installation schedule provided by the OEM prior to the machine’s arrival.

- Managing labour to continue working through the Easter break.

- Deadlines for decommissioning of the old factory.

Once the machines were out of the old factory we were tasked with decommissioning the existing services and cleaning up.

The new machine was installed ahead of schedule and below budget. The relocated machine was installed ahead of the revised schedule (due to the fire) and on budget and the old factory was decommissioned on time prior to hand over to the landlord.

This project was completed in conjunction with Machinery Relocations Limited and Matched Limited.